Data-Driven Defect Reduction

Summary

"We're seeing spikes in defective shipments, but we don't know why."

I built a custom, microcontroller-based monitoring device, which captured ambient temperature and noise data across varied seasonal and operational conditions. I then built a full data pipeline that ingests, transforms, and analyzes the data to identify correlations between environmental conditions and defect rates during order packing.

- Role — Data pipeline architect, dashboard developer, prototyping engineer, writer, researcher

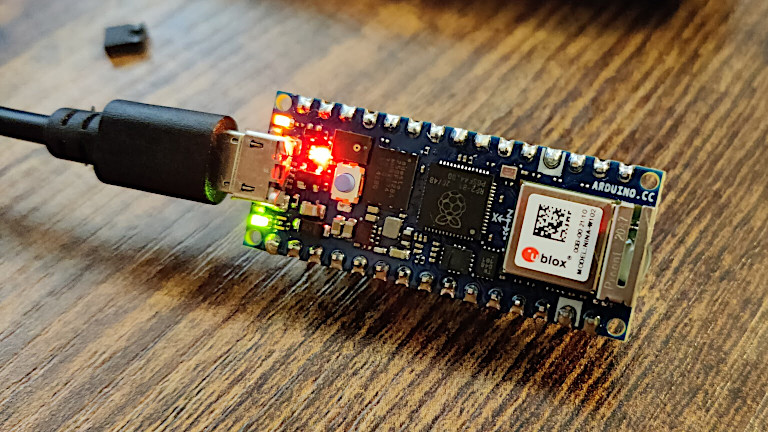

- Tools — Supabase (PostgreSQL + REST API), Python (pandas, seaborn, matplotlib), Streamlit, CircuitPython (RP2040 Connect), Jupyter

I delivered a complete cloud-connected, sensor-to-dashboard setup featuring physical computing, data engineering, and operational analysis that supports real-world fulfillment insight and experimentation.

This case study reflects the kind of work I do for clients: building lightweight, insight-driven systems that connect real-world behavior to measurable outcomes.

Gallery

A conceptual layout designed for this scenario, balancing realism with constraints: one sensor node, minimal coverage gaps, and plausible airflow and noise exposure near packing activity.

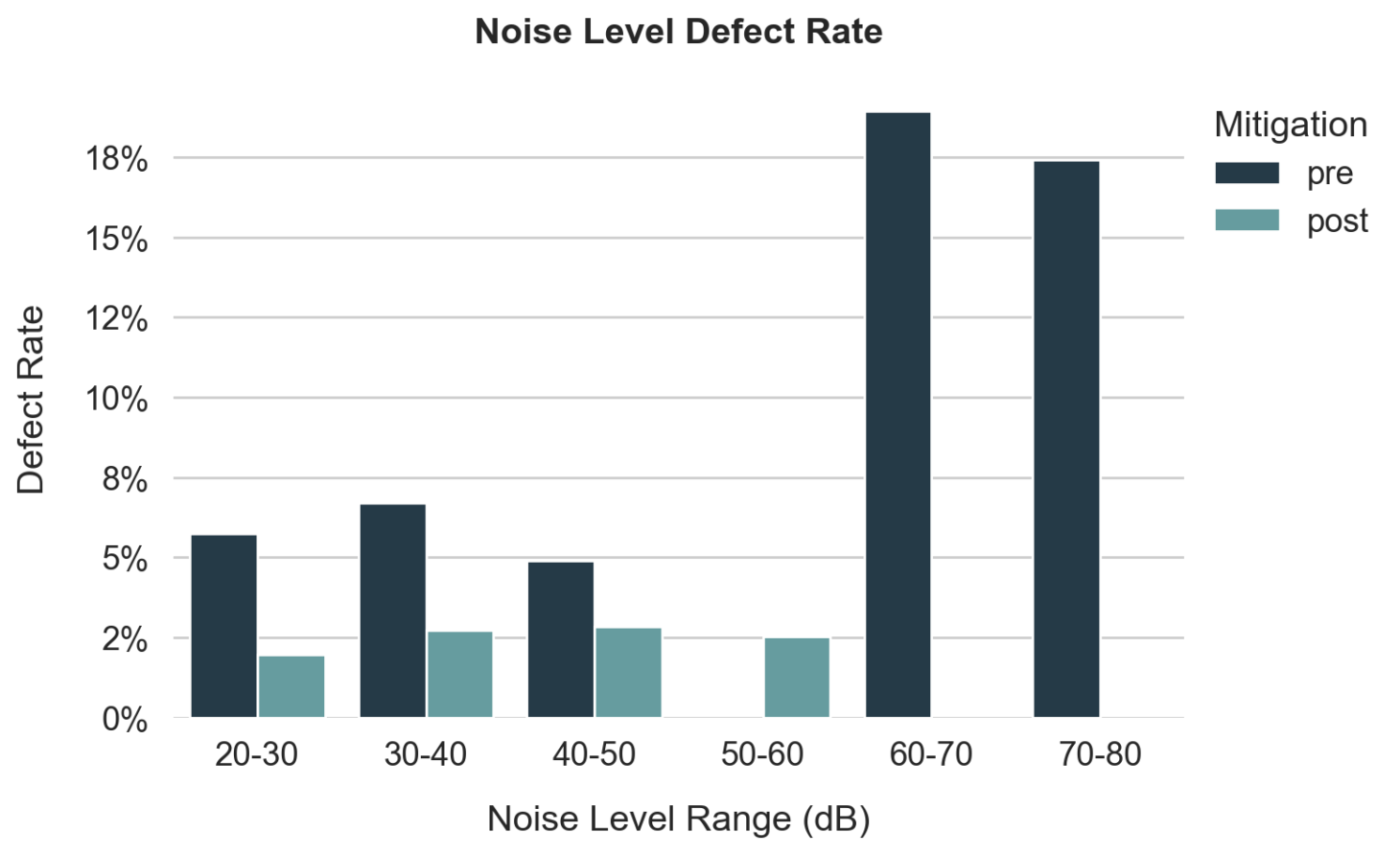

Pre-mitigation analysis revealed a sharp increase in defect rates above 60 dB, highlighting potential disruptions tied to ambient machinery noise.

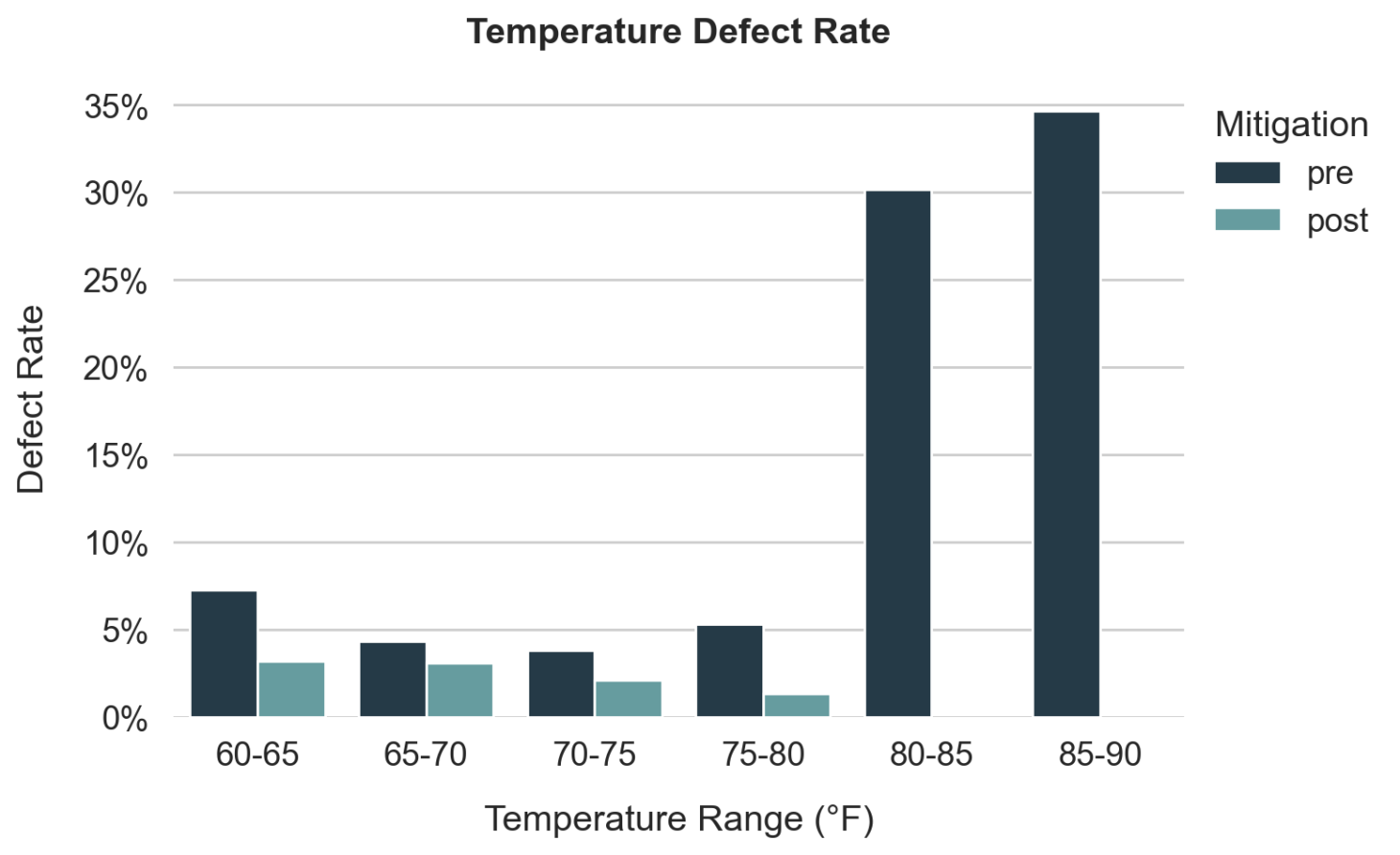

Defect rates increased significantly above 80°F prior to mitigation efforts, suggesting heat stress or other issues in the packing environment.

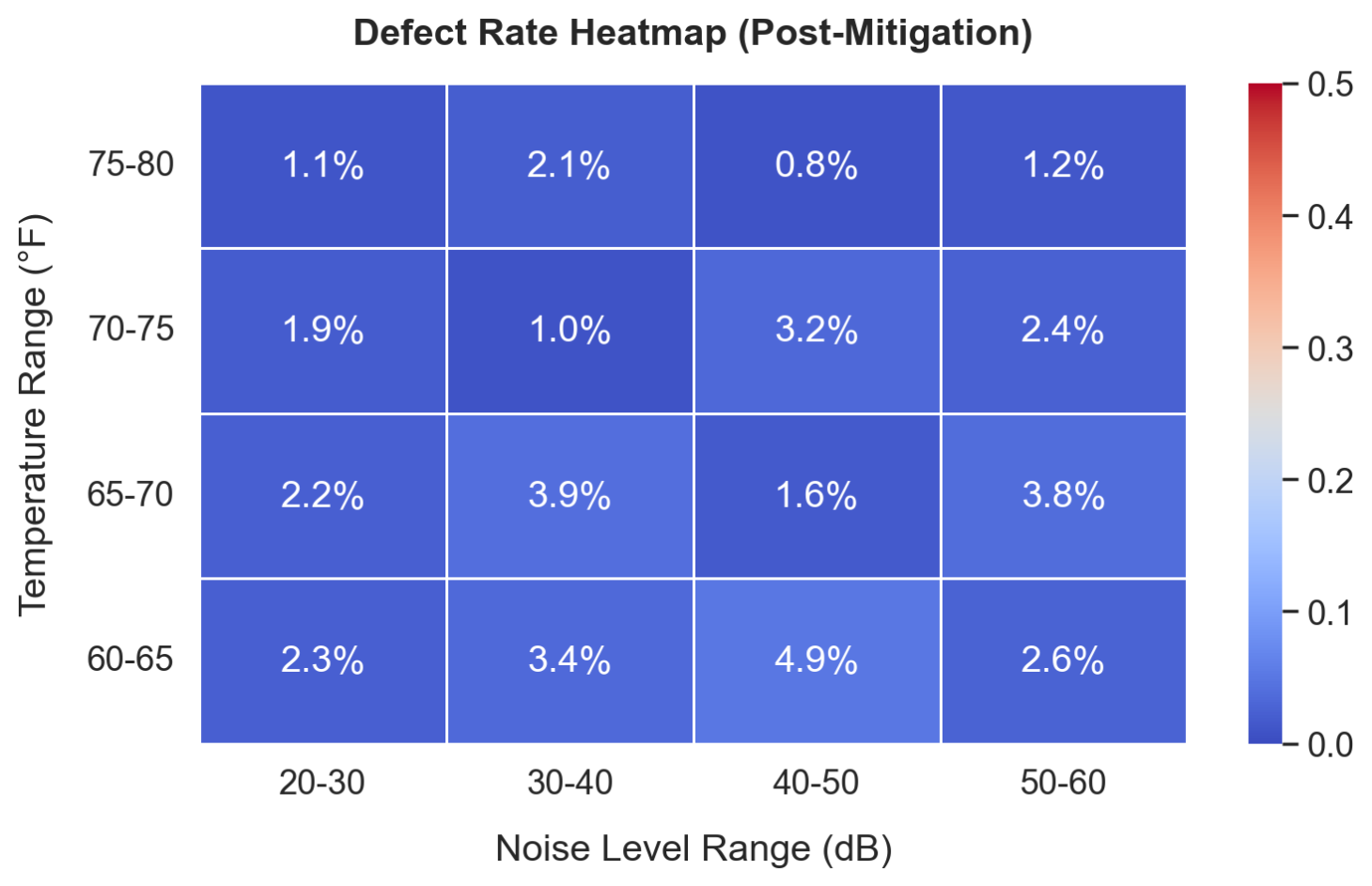

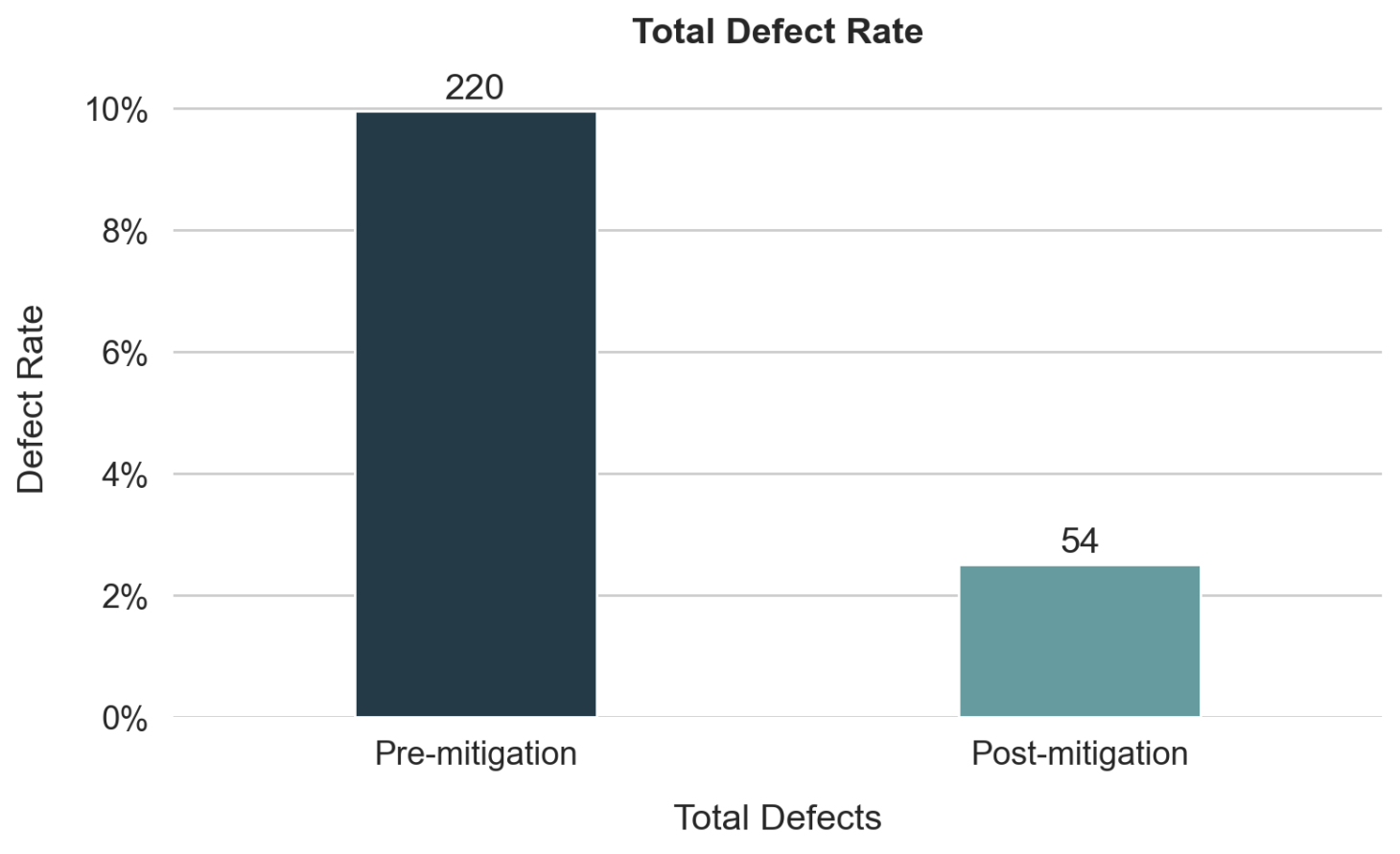

Post-mitigation defect rates dropped by over 75%, confirming the effectiveness of airflow, insulation, and acoustic damping upgrades.

Click an image for a closer look and more information.

Details

This system performs environmental data collection, takes in fulfillment error tracking, and performs defect correlation reporting using a simple, hardware-to-database-to-dashboard architecture.

- Microcontroller: RP2040 Connect running CircuitPython, chosen for onboard Wi-Fi, microphone, and temperature sensor

- Mounting: Simulated mounting in the pack area above the conveyor belt, pointed toward the packing station (in reality, no directional sensing required)

- Assumption: One sensor was sufficient given the modest warehouse footprint and layout

- Ambient noise: Modeled from fixed conveyance times (3 times per day), with random baseline ambient noise during off periods

- Database: Supabase PostgreSQL instance

- Ingestion: REST API used to post readings; separate table for operational order data

- Schema Design: Two primary tables:

order_fulfillment_dataandshipdock_environmental_data - Simulated Data: Generated testing data including realistic timestamps, defect types, box sizes, order sizes, shipping delays, etc.

- Correlation Design: Defect probability increased if temperature > 80°F and/or noise > 60 dB

- Binning: Temperature and noise values grouped into ranges for analysis

- Exploration: Conducted groupby aggregations and pivot-based heatmaps using pandas, seaborn, and matplotlib

- Dashboard: Streamlit app with dropdown-selectable views

- Charts: Three bar charts (temperature, noise, total defects) and two heatmaps (pre- and post-intervention)

- Mitigation Split: June-July modeled as baseline; August-September included simulated environmental improvements (fans, AC units, noise dampening curtains)

- A functioning warehouse insight system built from scratch

- Dashboard demonstrates clear visual drop in defect rate post-intervention

- Heatmaps show nuanced interactions between heat, noise, and error frequency

- Clean modular codebase, deployed with synthetic data and ready for adaptation

- Cold Weather Effects: Explore whether colder temperatures increase conveyance noise due to material contraction or lubricant changes

- Additional Sensors: Add humidity, motion, or light sensors for broader context

- More Granular Layout: Map zones of the warehouse to detect localized issues

- Production Integration: Adapt this prototype to push data to real-time ops dashboards or alerts

- Long-Term Mitigation: Consider warehouse-wide HVAC or reorganization for structural improvements

- Employee Feedback Loops: Use formal UX research techniques to survey workers and analyze responses, validate environmental impact, uncover overlooked issues, and inform future design

- An independent freelance project can still deliver real, actionable value when rooted in authentic experience

- Simulated data, when built with care, is a powerful tool for pre-testing hypothesis and demonstrating technical breadth

- Simple tools like Supabase, Streamlit, and Matplotlib/Seaborn are enough to tell compelling operational stories

- Engineering curiosity paired with UX empathy can yield credible solutions in complex logistics environments