Fulfillment UX Prototyping Infrastructure

Summary

"I want our lab to quickly test these fulfillment ideas like it's the real thing, without having to plug into a live warehouse."

I built a modular prototyping platform that replicated warehouse hardware, system responses, and user behaviors, which enabled fast, repeatable UX testing in both lab and field settings, without production system dependencies.

- Role — Developer, system designer, strategist, technical writer, data engineer, administrator

- Tools — Raspberry Pi, Node.js, WebSockets, MQTT, NoSQL, JavaScript (Electron, Express), 8020 extrusion, industrial barcode scanners and rack light buttons

The resulting system enabled flexible, realistic, and repeatable UX experiments for fulfillment center processes in lab and field settings.

This project reflects my broad approach: solving UX prototyping problems not just with code and components, but with reusable strategy and architectural clarity.

Gallery

An illustration depicting the physical nature of FC workspaces, highlighting the need for realistic prototyping.

An illustration of the modular test station setup used to explore human-computer interactions in fulfillment workflows.

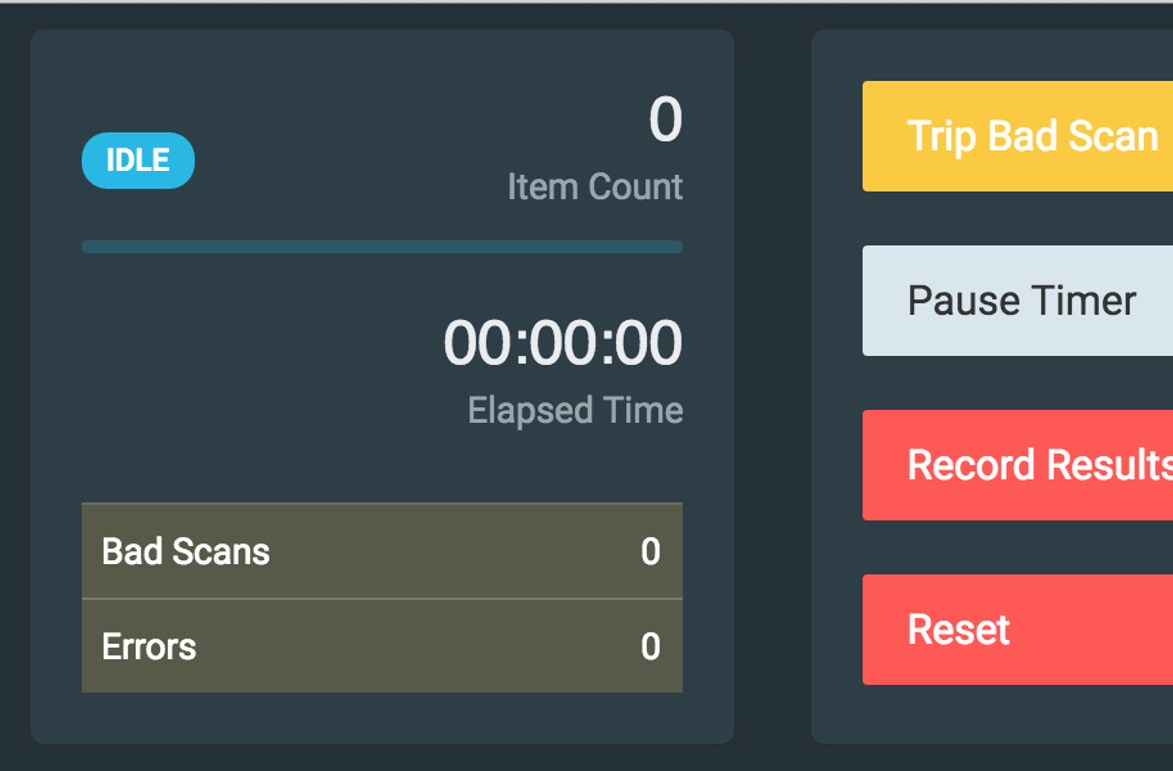

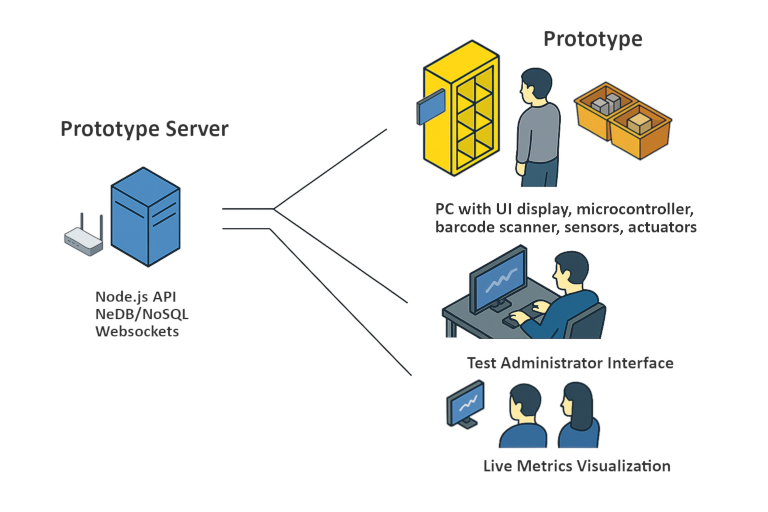

A portable Node.js-based prototype server powers all client interfaces — workstation UI, researcher dashboard, and metrics display via local API and WebSocket connections.

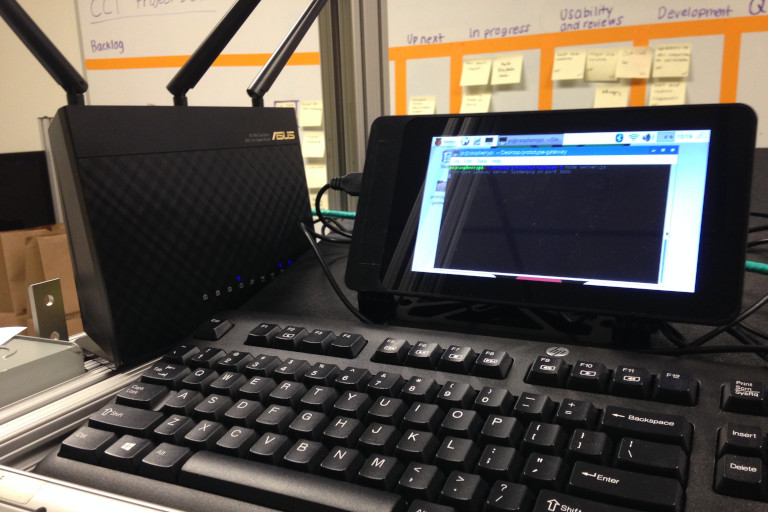

A Raspberry Pi with touchscreen display and a dedicated Wi-Fi router form a self-contained, offline-capable backend — ideal for field tests in fulfillment centers or wherever a workstation facsimile can be set up.

Click an image for a closer look and more information. (Note: Some visuals are illustrations created in place of confidential images.)

Details

I built a modular prototyping infrastructure to support interactive UX research, both in-lab and at fulfillment centers. My goal wasn't just to enable flexible testing — I designed the system as a reusable platform that could support both tactical UX experiments and vision-driven, future-state demonstrations. The architecture emphasized modularity, transparency, and a degreee of technical agnosticism, so it could evolve alongside both research questions and emerging technologies.

- Adapted the lab's existing 8020 extrusion frame and added configured components in parity with FC setups and standards (industrial barcode scanner, racklight buttons, touchscreen, totes, and bins)

- Implemented mounts and tooling for configurable layouts simulating various station designs

- Designed a flexible set of connections and cabling that allowed us to add or remove or devices on demand

- Developed a faux "product data system" backend using a Raspberry Pi + ASUS Wi-Fi router

- Created a NoSQL database with names, images, prices, and descriptions of in-lab test products

- Served a local Node.js API to serve product data

- Avoided reliance on corporate Wi-Fi at fulfillment centers, enabling portable, decoupled deployment

- Created a modular JavaScript UI (Electron) with swappable screens, UI states, and event logic

- Integrated real-time WebSocket handling for inputs and messages, including barcode scans, button presses, camera triggers, racklight activations, and IoT events

- Built a separate admin interface for researchers to trigger test events or observe sessions remotely

- Authored internal API and system documentation for onboarding and reuse

- Wrote a related white paper proposing prototyping architecture standards informed by this and similar projects

- Refactored the system over time to support both local and cloud-based setups, using the portable backend for most testing, and connecting to AWS IoT or services like Lex and Polly when remote messaging or speech interaction was required

- Enabled realistic, unscripted UX testing with physical components and simulated product workflows

- Supported rapid iteration and seamless integration of emergent hardware technologies

- Reduced time to insight by surfacing usability issues earlier in the design process

- Increased confidence among designers and researchers in the fidelity and reliability of prototypes

- Expanded the lab's capacity to explore long-range, proactive concepts, supporting not just tactical problem-solving, but also three-to-five-year planning

- Served as a platform for vision prototyping, enabling theater-style, immersive demonstrations of future-state concepts, including experiential training systems that responded dynamically to user actions and performance

- Formalize a component library of hardware and UI building blocks to accelerate future prototype development

- Extend the architecture to support integrations with emerging technologies like VR and AR

- Open-source a version of the infrastructure for academic or industrial R&D teams working in similar UX domains

- Incorporate machine learning for safety-focused use cases, such as pose analysis to help prevent injuries, or alertness detection to support worker well-being

- A modular infrastructure like this enables not just better UX research, but a culture of rapid validation and long-term thinking in operational contexts.

- Strategic design for portability and flexibility allows tools like this to stay useful even as test scenarios and technologies change.

- Codifying the architecture and publishing internal standards helped the team scale experimentation more efficiently and with greater clarity.